Polypropylene reigns supreme in the realm of packaging materials. This adaptable polymer is a frequent go-to when discussing grocery bags, yogurt containers, bottle caps, or many other everyday items.

But why is polypropylene so popular? Learn the answers to that question by deeply diving into this extensive guide.

What is polypropylene?

Polypropylene, also known as PP, is a versatile thermoplastic polymer with a unique ability to be heated, reshaped, and cooled repeatedly without losing its initial properties. This trait has allowed the material to fit seamlessly into a broad spectrum of products.

Although polypropylene is made from petroleum, it’s a relatively sustainable material. It can be recycled easily, and it doesn’t release harmful chemicals when it is burned. This property makes it an environmentally responsible choice for packaging and other applications where the impact on nature is a critical consideration.

Types of polypropylene.

There are two main types of polypropylene: homopolymers and copolymers. Homopolymers are made up of repeating units of propylene, while copolymers contain a small amount of other monomers, such as ethylene. This gives copolymers additional flexibility and makes them easier to process.

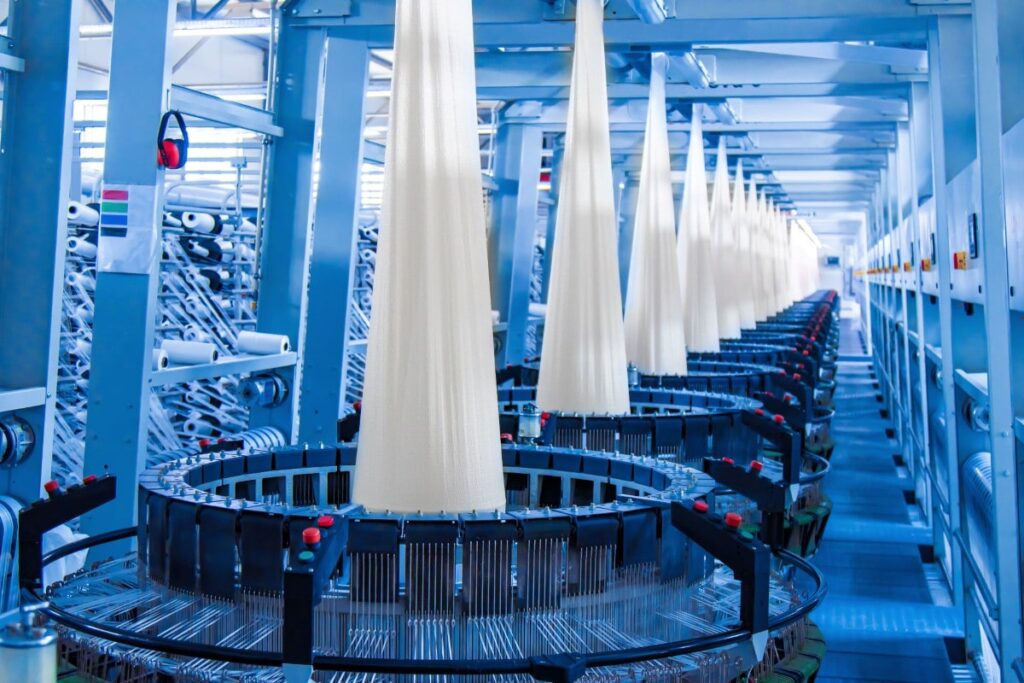

One of the most notable properties of polypropylene fabric and other forms is its resistance to wear and tear. This makes it ideal for applications where durability is important, such as reusable shopping bags and industrial filters. Polypropylene is also a good insulator, making it a good choice for electrical applications.

So, now that you have an idea of what polypropylene is, check out why many businesses worldwide use this versatile material for product packaging.

1. It’s affordable.

Polypropylene packaging ticks the affordability box with an attractive cost-effectiveness ratio. This stems from its relatively low manufacturing costs and high-performance properties. With polypropylene, businesses can balance their budgets without skimping on the packaging quality, thereby providing end-users with reliable products without a high price tag.

2. It’s durable.

Polypropylene’s durability is a primary draw. The material stands firm against various external stresses, from physical impacts to harsh weather conditions. This resilience minimizes the risk of damage to the packaged goods, providing dependable protection that you and your customers can trust.

Due to its high tensile strength, polypropylene is an excellent material for packaging products from all trades. But the food industry is not the only one utilizing it. Fashion, sports, automobiles, and even medicine—you name it! They likely have a use for it.

3. It’s Flexible.

With its thermoplastic nature, polypropylene is a master of flexibility. It can morph into numerous shapes and forms, adapting to unique product needs. This adaptability opens up a world of packaging possibilities, from custom-fit containers to innovative and engaging product designs.

4. It’s lightweight.

The lightweight nature of polypropylene reduces the overall weight of packaged goods, making transportation easier and more cost-effective. This lightness doesn’t compromise strength or durability, showcasing the material’s excellent balance of properties. Lower transportation costs translate into economic benefits for businesses and decreased environmental footprint, a win-win scenario.

5. It’s non-toxic.

Polypropylene serves as a safe and BPA-free alternative to other plastic-derived packaging materials. Bisphenol A, or BPA, is a chemical that’s been used in the manufacturing of plastics and resins for many years.

While the FDA maintains that minimal amounts of BPA pose no threat to humans, some health and environmental experts express concerns about excessive exposure, suggesting it may lead to certain health issues. These include learning impairments and brain development concerns in children.

With the lack of BPA, polypropylene’s non-toxicity is generally safe for consumers. It doesn’t leach harmful chemicals into the product it’s protecting, making it a safe choice for food packaging and medical supplies. This characteristic bolsters consumer trust, enhancing the appeal of polypropylene packaging.

6. It’s water resistant.

Polypropylene is water-resistant to a certain extent, and this property provides an extra layer of protection for packaged goods. It prevents moisture from seeping into the product, preserving its integrity and quality, even in humid or damp environments.

However, it’s essential to remember that not all polypropylene products are treated for total water resistance. Manufacturers may opt for additional waterproofing, so it’s a good idea to conduct a package test to ascertain its moisture-repelling capabilities.

To determine if a polypropylene item has been waterproofed, conduct a package test. Pour water on the surface of the item. If the water beads, then the item has water-resistant qualities.

7. It’s resistant to chemical corrosion.

Polypropylene proves its worth in the face of various chemicals, too. Its inherent chemical resistance protects products, particularly those that are chemically sensitive. It’s an excellent packaging choice for cleaning products, pharmaceuticals, and any product where chemical interaction could be a concern.

8. It’s customizable.

Polypropylene’s customizable nature goes beyond size and shape. It allows for a broad palette of colors and finishes, opening doors for aesthetic appeal and branding opportunities. Therefore, you can opt for basic polypropylene boxes or containers in custom shapes to perfectly package every inch of your product.

Beyond visuals, the material’s functional attributes can be tailored for specific performance needs, offering an adaptable solution for a wide range of applications.

9. It’s recyclable.

Last but far from least, polypropylene is recyclable. It can be melted and reshaped into new products, supporting an economy where materials are reused instead of discarded. This trait aligns with the increasing global emphasis on sustainability, adding another feather to polypropylene packaging’s cap.

Recycling helps reduce environmental impact and contributes to resource efficiency, providing both ecological and economic benefits.

Recyclable packaging and products may not be the first thing in a startup business investment plan, but it’s a wise consideration for new business owners. With many people leaning more toward sustainability, more establishments are following suit with recyclable or reusable package and storage options. Incorporating polypropylene in a retail business’ packaging ensures product protection and contributes to less plastic waste.

Final thoughts.

As you can see, polypropylene stands tall as a versatile, durable, and cost-effective packaging solution. It’s a choice that brings together practicality and sustainability. So, as you consider packaging options, remember the power of polypropylene. It could be the difference your business needs in this increasingly competitive, environmentally conscious market.