The manufacturing industry is one of the biggest beneficiaries of modern technology. From Robotics and 3D printing to big data and the Internet of Things, there are many novel techniques and methodologies that are driving growth and innovation in numerous sectors. These days, however, manufacturers are also under constant pressure from market and regulatory bodies to produce high-quality products, whether they be individual components or actual finished commodities. This is why the manufacturing industry is always looking for solutions to make their jobs easier, faster, more efficient, and more cost-effective.

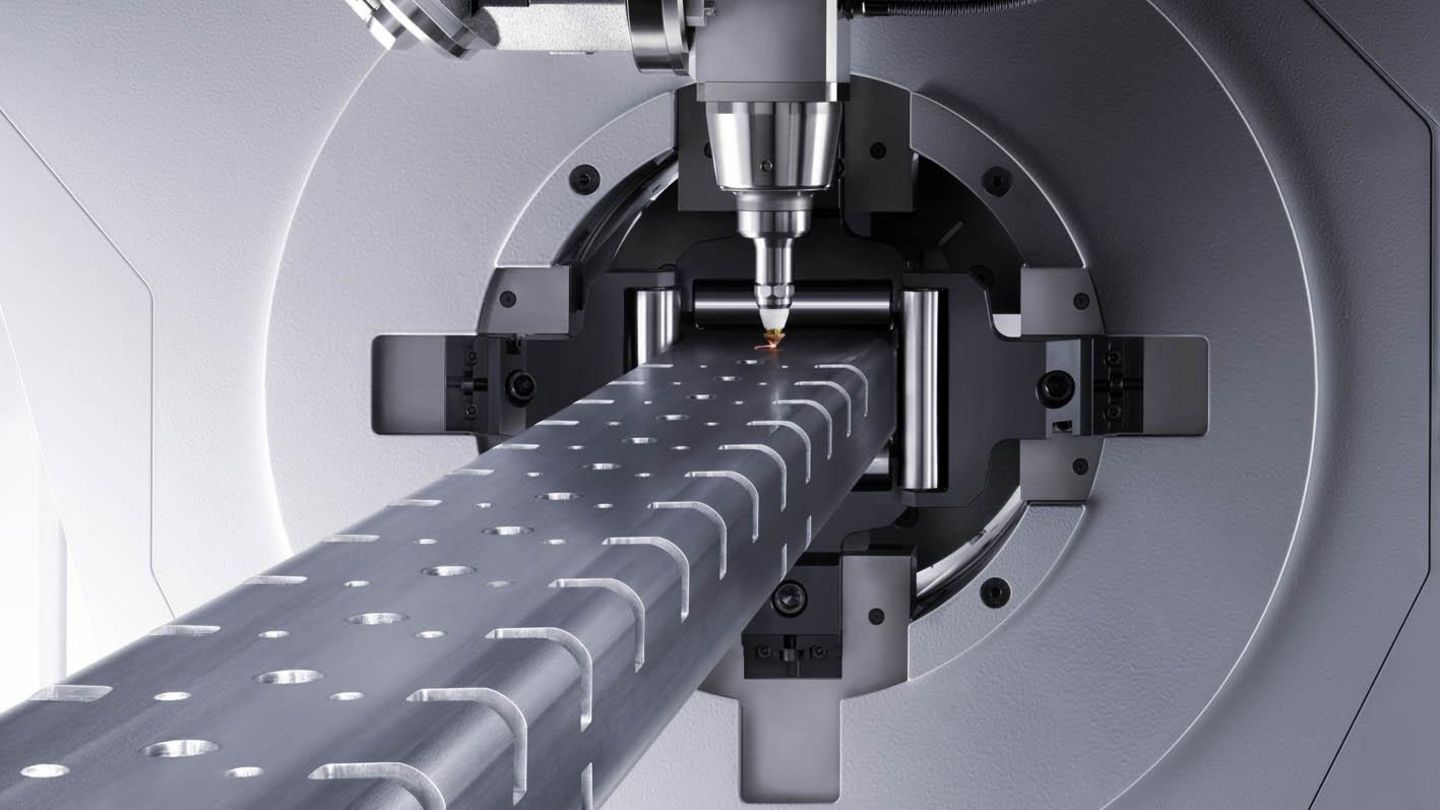

Among the more prominent technologies used in modern manufacturing is laser processing of materials and micro-materials. Laser cutting, welding, drilling, and marking or engraving are only a few of the laser applications that have made a difference in manufacturing different products like gadgets and appliances, medical equipment, and components for automotive and aerospace engineering.

High-Level Precision and Accuracy

Most of the latest models of laser cutters have positioning accuracies of up to 10 micrometers and repeatability of 5 micrometers. This level of precision and accuracy is especially important when manufacturing delicate equipment like those intended for patient care or for mission-critical engineering applications.

Laser cutting also results into burr-free edges and smooth surfaces—think of laser-cut edges in metal, plastic, or fabric workpieces. Laser-cutting machines are typically equipped with high-quality XY stages so that they can be operated with a greater level of control, ensuring that intricate patterns can be created without losing dimensional tolerances.

Meanwhile, laser drilling can create holes with diameters as small as 0.0005 inches in a wide range of materials—from rubber and plastic to stainless steel and titanium—with different levels of sensitivity. Laser welding, on the other hand, delivers small welds that are not only smooth and neat, but also stronger than conventional welding processes.

Wear and Tear Resistance

Laser marking or engraving is used to etch designs or product information onto different workpieces. Marks and labels made with the help of lasers are more resistant to fading, making them an ideal choice for engraving medical equipment, which are usually subjected to high temperatures during sterilization.

Laser processing can also be useful in garment manufacturing. For example, clothes with laser-cut edges don’t fray, as the heat from the laser effectively “seals” these edges. Another advantage of laser cutting is that there is no additional pressure to the fabric, which is especially valuable when working with delicate fabrics like lace or silk.

Efficiency and Safety

Laser cutting reduces the number of equipment needed, as one laser cutter can be retrofitted to be able to cut different materials—from the most durable metals to the most delicate fabrics. Because only the laser touches the surface of the material to be cut, repair and maintenance costs are also lowered.After all,there are virtually no cutting parts that come into contact with the workpieces. Laser processing equipment also use less power in general, further lowering operational costs for the manufacturers. For example, laser cutting machines use only around 10 kW of power, whereas other processes and equipment use upwards of 50kW.

Meanwhile, laser welding reduces thermal distortion. This makes the process ideal for welding metals with different heat tolerance levels, attaching metals to plastic components, or when using heat-sensitive assemblies.

Finally, laser processing is also safer compared to other traditional manufacturing operations. Due to minimal contact with the workpieces, the process reduces electrostatic discharge, moisture, friction, and other elements that may affect the product output. Laser processes also minimize sudden or extreme temperature shifts, which can affect the integrity of the equipment.

The laser processing market is expected to be valued at around$16.05 billion by the year 2020. With its immediately appreciable benefits to the manufacturing industry, more industries are also following suit in adopting laser processing methods.These applications include oil and gas exploration, medical procedures, and manufacturing cost-efficient homes and automotives.